Cleaning a professional oven is essential to have the equipment functioning correctly. Only a properly cleaned oven can operate to its full potential and guarantee the consistent product quality of the products cooked or heated inside. As all those who work in the restaurant world know well, managing cleaning activities, however, in the best way possible is not always simple.

First of all, cleaning an oven is an activity that requires time and can impact on the organization of the kitchen or laboratory as a whole since obviously during the cleaning and descaling phases of the oven it cannot be used to carry out normal activities. Adequately planning the time dedicated to cleaning is therefore essential in order not to deal with unnecessary and unexpected situations.

Another aspect that should not be underestimated is the costs related to cleaning activities, which should be carefully considered when calculating the total cost of ownership of an oven. The expenditure items that should not be forgotten and need to be evaluated include the following:

- Cost of water used for cleaning

- Cost of detergents, additives and descalers

- Cost of the energy required to heat water and/or complete the cleaning programs

Automatic washing system ovens vs manually cleaned ovens

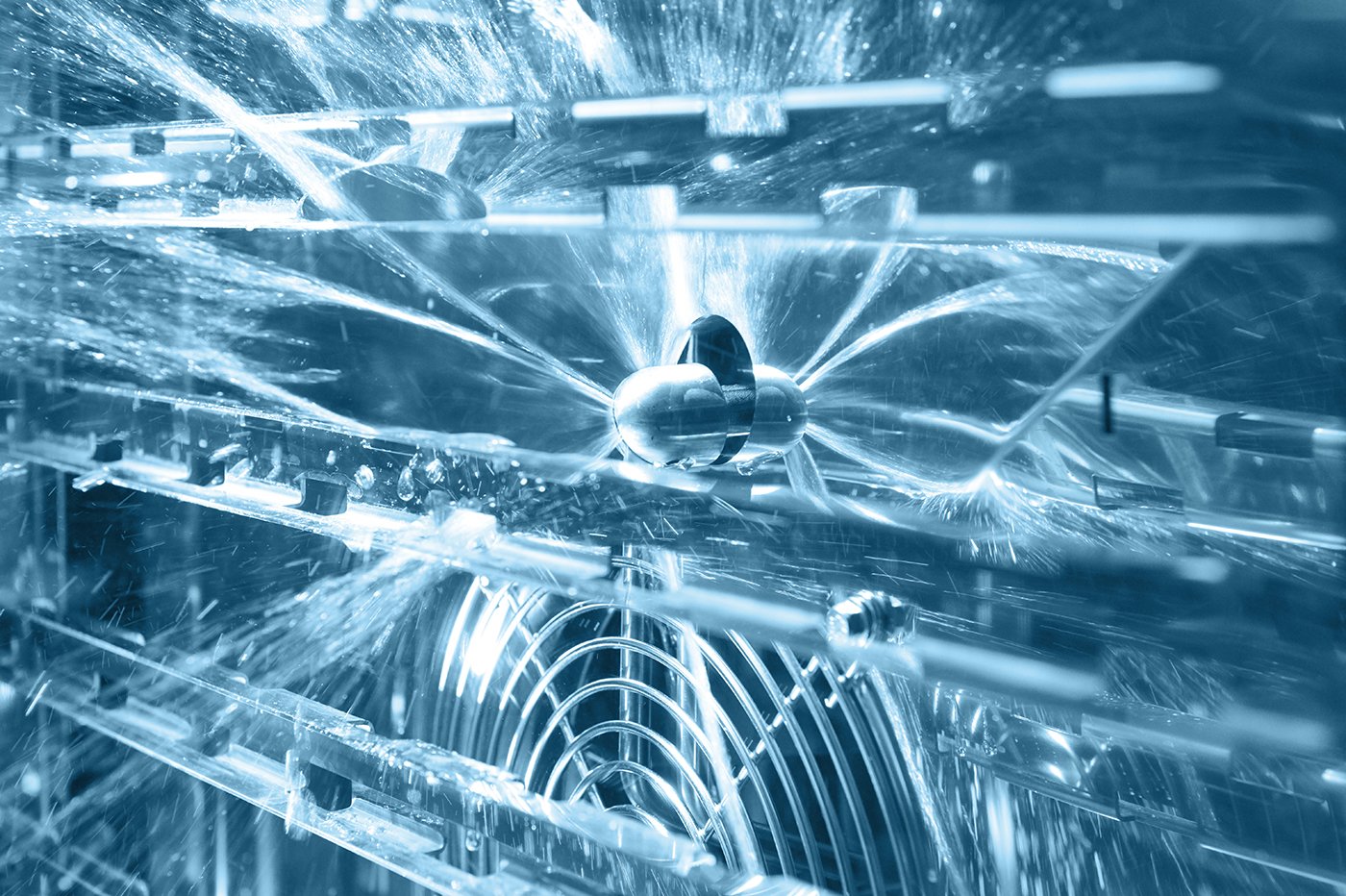

Professional ovens are often equipped with automatic washing systems, which independently carry out cleaning activities programmed by the user.

An automatic cleaning system guarantees big advantages. It not only allows operators to optimize their work time since they don’t have to stop their normal activities to manually clean the oven, but it also ensures that cleaning is done in a particularly efficient way as water reaches much higher temperatures than reached during manual washing.

Carrying out an automatic oven washing obviously requires a certain investment in terms of energy and organizational effort since automatic cleaning programs normally last longer than manual cleaning and can therefore "block" the oven from being used, even just for a few hours. But by organizing the washing cycles correctly and programming them outside the kitchen's normal active use periods, automatic washing cycles can still guarantee big advantages in both economic and practical terms.

Furthermore, automatic cleaning is carried out with specific products which are specially designed to as to never damage oven surfaces or electrical and electronic components. As a result, the correct maintenance of the oven is guaranteed which is fundamental as the oven is also ready to perform at its best and even better in the long run.

What detergent to choose?

A professional oven must be cleaned with special detergents, which are capable of guaranteeing performance without polluting the environment. In order to get the best results, it is essential to choose professional ecological detergents. Currently, there are many different types of products specifically designed for cleaning ovens on the market.

Detergents can be found in solid or liquid form. The advantages of solid form detergents include that storage is easier as it takes up less space and allows kitchens to have an abundant stock on hand. Solid detergents, however, extends the washing time since the product must be dissolved before it is used. The detergent dissolving phase not only requires a greater investment of time, but also of energy. This can be avoided by choosing a liquid detergent, which are even better if pre-mixed with additives and a descaler.

When to descale

Professional ovens not only need to be cleaned frequently, but they also need to be descaled periodically in order to remove limescale that could deposit in the boiler and other oven components.

This process is essential to permit the oven to always work efficiently, and it is, therefore, important to carry it out regularly using special products. The frequency with which to perform this process may vary depending on the hardness of the water used, but normally it is necessary to do it at least once a month.

Lainox solutions for cleaning professional ovens

Lainox has developed various solutions to simplify the cleaning of its professional ovens, all equipped with automatic washing systems.

In particular, here is what customers who buy Lainox products can count on:

- Short cleaning cycle: Lainox has worked hard to reduce the duration of the washing cycles of its ovens as much as possible. This allows customers to save energy and manage cleaning activities in the best possible way, without affecting the normal organization of the kitchen.

- Professional detergents with deposited formula: Lainox has developed a detergent specifically designed for cleaning its ovens. Customers who have purchased a Lainox oven can request the supply of this professional detergent, already available in liquid form. It is sent directly from the manufacturer and guarantees excellent performance in terms of cleaning and sanitation. A descaler has also been added to the detergent and, therefore, allows you to obtain ovens that are not only thoroughly clean, but also, always perfectly shiny.

- Vapor Cleaning System: Lainox has developed a special vaporisation system to optimize detergent use which allows the cleaning product to be distributed inside the oven in a particularly efficient way. In this way, waste is avoided and the environment is protected, while at the same time obtaining impeccable

- Cal-Out Alert System: Finally, the Lainox combi ovens are equipped with a control system which signals the need to descale when the amount of limescale exceeds the set threshold. In this way, it is possible to always have a perfectly efficient oven and limit waste as much as possible, since descaling is not carried out at predefined intervals, but only when there is an actual need.

Would you like to know more?